How to install a Temket universal insulation jacket?

The universal insulation jackets from Temket are specially designed for use in utility applications. Think of boiler rooms in a wide variety of buildings such as offices, schools, swimming pools, sports clubs, distribution centers, and wholesalers. The product line consists of three types of jackets:

- Insulation jackets for fittings (Type A)

- Insulation jackets for pumps (Type B)

- Insulation jackets for pipe sections (Type C)

These insulation jackets come in various sizes, allowing you to insulate common fittings and pumps yourself, resulting in considerable cost savings. But how does installing an insulation jacket work, and what should you pay attention to? You’ll find all the details in this article.

Step 1 – Determine size and specifications

To use universal insulation jackets, certain specifications apply. Always check the following to ensure an insulation jacket fits the object to be insulated. Are there mounting brackets, valves, or protrusions that might obstruct jacket installation? If brackets can be (temporarily) removed, this will not be an issue. If valves or other protrusions are included, the circumference at these points should be used as a reference measurement. Additionally, ensure at least 20 mm of clearance around the object to be insulated. With these specifications in mind, you can select the appropriate jacket size.

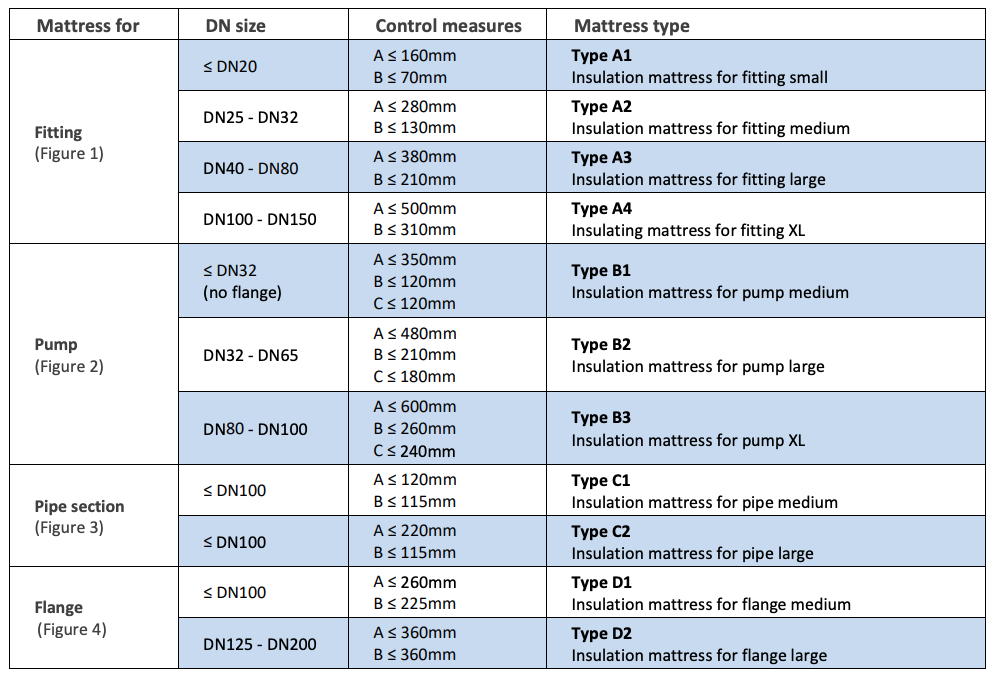

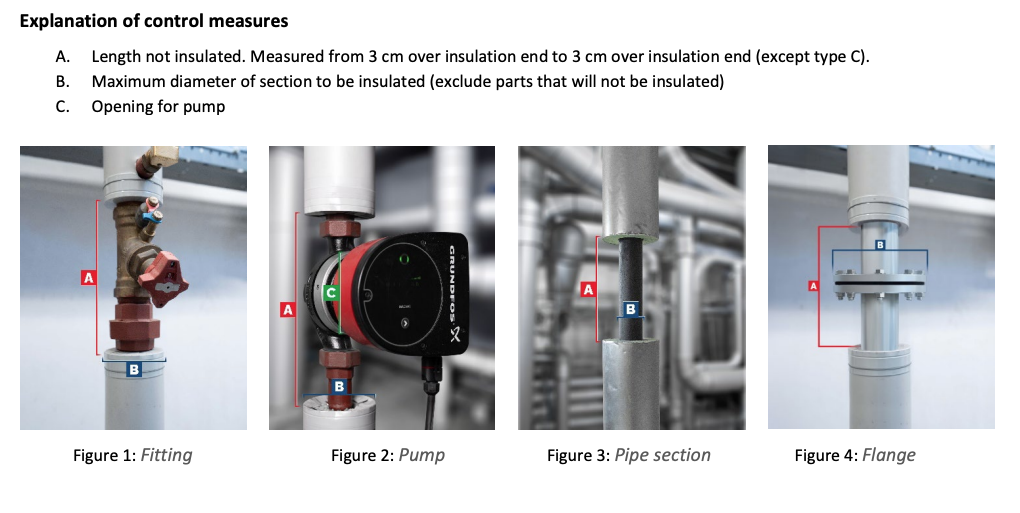

Fittings

For various fittings, such as valves, butterfly valves, pressure-reducing valves, and filters, select one of the four Type A fitting insulation jackets based on the DN size or circumference of the fitting. It is advisable to check the reference measurements provided on the technical datasheet.

Pumps

Universal insulation jackets for pumps are available in two sizes. The medium jacket (B1) is suitable for use up to DN32, and the large jacket (B2) can be applied to pumps up to DN100. Given the wide variety of pumps, it is always advisable to check if the pump dimensions match the reference measurements on the technical datasheet and in the table below.

Pipe sections

For non-insulated pipe sections, two sizes of universal jackets are available. The medium insulation jacket (C1) is suitable for a non-insulated pipe section up to 120 mm in length. For non-insulated pipe sections up to 220 mm, choose the large pipe insulation jacket (C2). Both types are suitable for pipes up to DN100, or a diameter of 100 mm.

Step 2 – Safety

Before installing insulation jackets, it’s important to take several safety precautions. The edges of the metal casing may have sharp parts. Therefore, it’s recommended to wear gloves during installation.

Step 3 – Installation instructions per type

Type A – Fittings

Depending on the size (A1 to A4) of the fitting insulation jacket, there will be more or fewer Velcro closure strips, but the installation process remains the same.

- Open all the Velcro closure strips.

- Slide the fitting as far as possible into the opening created.

- Then fasten the Velcro strips as tightly as possible around the fitting.

- Wrap the remaining part of the jacket around the fitting and pipe.

- Attach the Velcro, pull the strings, and tie a knot.

Fitting to be insulated

Place the fitting in the insulation jacket

Correctly insulated fitting

Type B – Pumps

The insulation jacket for pumps is slightly different.

- Open all closures.

- Place the pump’s opening through the cross created.

- Ensure that the top and bottom are centered.

- Fasten the Velcro strips tightly around it.

- Wrap the remaining part of the jacket around the pump and pipe.

- Attach the Velcro closure and pull the string tight.

Pump to be insulated

Place the insulation jacket around the pump

Correctly placed insulation jacket around the pump

Type C – Pipes

The universal insulation jacket for pipes is the simplest to install.

- Keep the side with the loops (the soft part of the Velcro) facing you.

- Hold the jacket with one hand and pull it tightly around the pipe with the other.

- Attach the Velcro. The Temket logo will now be at the front.

Uninsulated pipe section

Wrap the insulation around the pipe section

Correctly placed insulation jacket around the pipe

In addition to these three applications, other applications such as three-way valves are also possible. Want to know if your specific situation is feasible? Use our advisory service. You can easily send one or more photos with descriptions through our website, so we can assess the situation and recommend the appropriate insulation jacket.

Custom insulation jackets or prefer installation by us?

Prefer to have the jackets installed by us after reading these instructions? We’d be happy to connect you with one of our specialists. The Temket Universal Line is suitable for hot water and heating systems. If you need insulation jackets for higher temperatures or industrial applications, we also offer high-quality custom insulation jackets!